【Networking Power Supply】Fanless Power Supply Design Enhances Power Conversion Efficiency

With the development of global 5G technology, the demand for high-speed servers and switches is going to increase dramatically within the next five years. As the bt standard for new PoEs (Power over Ethernet) rapidly evolves, the power demand has grown by multiple folds. As consequence, the amount of heat generated is only going to increase. Therefore, being able to design a high-speed network switch that is capable of stable operation within an high temperature environment is crucial. With advancements in quality and technology of electronic parts, cooling fans directly impact the lifespan and stability of network switches.

As a cooling fan operates for an extended period of time, numerous problems will begin to appear, such as the accumulation of dust, wearing of spindles and the aging of fan leaves. This will result in increasingly louder fan noises until the fan eventually malfunctions. Fan failure will cause overheating and lead to a whole variety of problems.

Adopting a fanless design can totally eliminate these problems. The biggest advantage of the fanless design, is the enhancement of power conversion efficiency! Take POE 200W system as an example. If the power efficiency is 80 Plus Bronze certified (82% at full load), the power loss will be

(200÷0.82)-200=44W

The system’s internal power energy loss is about 20W, which is much lower than the 44W of the power supply. (The remaining 180W is for back-end equipment.) On this account, elevating power supplies’ work efficiency is the primary goal of the fanless design.

Regarding how to design a higher efficient power supply with better stability, Asian Power Device has a complete and comprehensive design procedure:

1. Use cutting-edge circuit technology within a reasonable topological structure to create a solid foundation and to achieve excellent efficiency

2.Use an electronic theoretical arithmetic platform for rapid calculations, which can not only identify the the best transformer structure, the optimised working frequency models, and the best power components, but is capable of calculating the differential loss of various kinds of models.

(A – J represent the power loss of each key components such as transformer, capacitors, semiconductors, and resistors.)

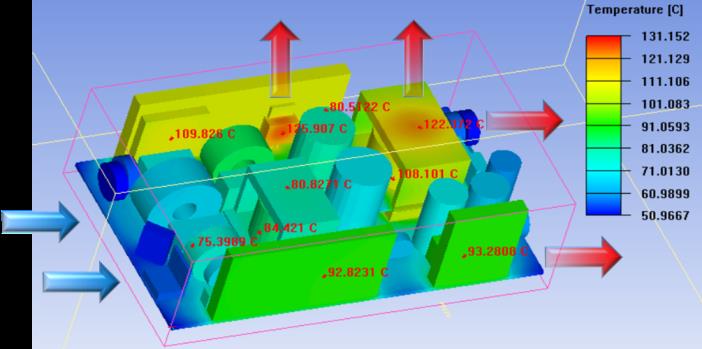

3. Use the differential loss obtained in Step 2 to conduct a thermal flow simulation, and optimize the design of PCB layout and heatsinks.

3. Use the differential loss obtained in Step 2 to conduct a thermal flow simulation, and optimize the design of PCB layout and heatsinks.

4. Tolerance analysis: Determine the ultimate parameter range for each component,and then control these parameters to enhance stability for the manufacturing performance (DFSS).

5. Utilize the latest DFMEA (Design Failure Mode and Effect Analysis) to identify the potential failures and control the noise to lower mass production failure rates.

Asian Power Device implement this complete design processes to produce an exceedingly efficient and price competitive fanless power supply. With professional testing equipment, lab facilities and research team expertise, APD is able to achieve the following:

- EMI Chamber: Able to conduct EMI test in compliance with clients’ products in the early stages of development and promptly respond to their needs.

- High-end surge protector: APD possesses specialized research teams as well as testing equipment in overcoming the difficulties in designing surge protectors.

- Research and development team: APD’s R&D team consists of 30 DFSS black belts and 16 green belts, which contribute to highly efficient, stable, and price competitive products.

- Safety and regulation lab: Having acquired UL CTDP/IEC CTF Stage 3 certificates, APD can adjust and customize services to fulfill safety regulation needs of every client, and at any given time.

Asian Power Device’s Fanless Power Supply is the Optimal partner for PoE Switches.